At ZohFye Motion, we believe transparency and rigorous performance testing are essential. These results demonstrate our commitment to precision engineering and our community’s trust.

Huge thanks to Abeiku, our Full Time Engineering Co-op Student who took the lead in compiling and executing this summary and full test report. I had the pleasure of hiring him last year as a Full Time Engineering Co-op while working at Sienci Labs. Since then he has taken what I taught him about laser product development and was able to grow and refine his knowledge. I am glad to have him back working on new laser product development.

Methodology

When it comes to validating the quality of a CO2 laser, there is no standard procedure that is widely recognized throughout the industry. Thus, we had to design experiments and procedures that would allow for the collection of data that could yield useful information about the performance of the model.

One of the most crucial characteristics of a CO2 laser is its precision, or more specifically, its repeatability. Repeatability is defined as a CO2 laser’s ability to move its laser head to the same position over multiple operations or cycles. Thus, a machine with excellent repeatability can be moved smoothly, generates precise and clean shapes, and does so consistently.

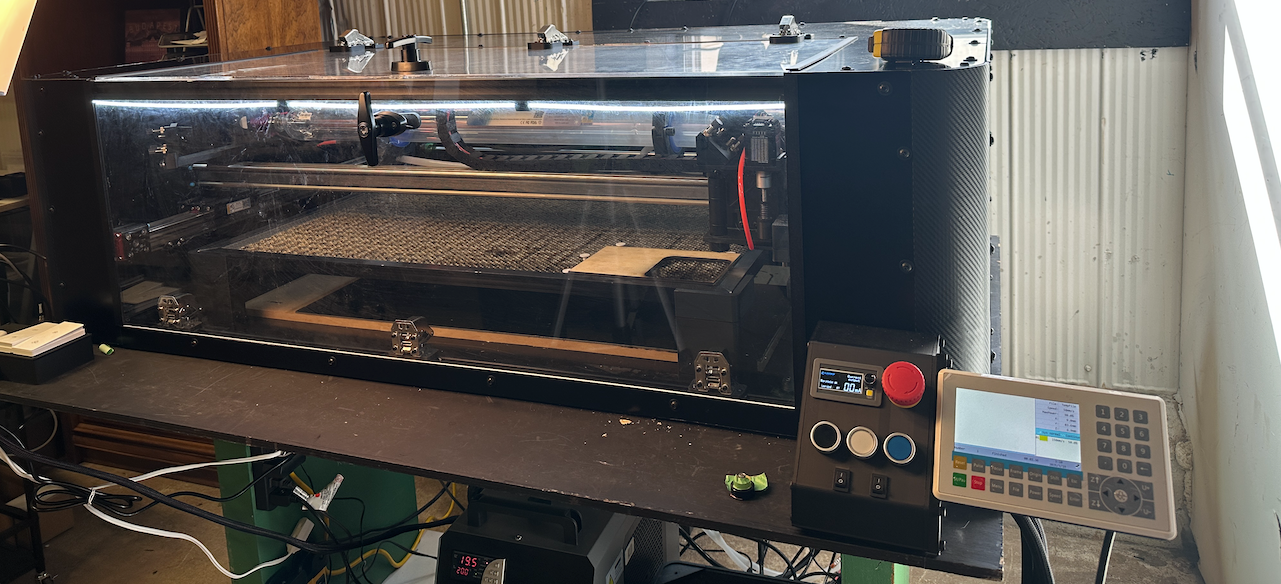

Due to these factors, we decided that one of the best ways to express the quality of the ARC Maker was to test its repeatability and experimentally determine an appropriate tolerance range for the machine’s precision. Across 320 trials, with varying movement directions and speeds, the laser head gantry was moved back and forth to a certain position, with the variation between each movement (if any) being measured with a dial indicator.

Testing

Repeatability Test Setup With Dial Indicator (X-Axis)

Test Results: Summary

The results were quite electrifying and are summarized in the table below:

|

Movement Direction Tested |

Average Deviation Across 40 Trials (mm) |

Maximum Deviation Across 40 Trials (mm) |

|

+X |

0.00075 |

0.01 |

|

-X |

0.00075 |

0.01 |

|

+Y |

0.00075 |

0.01 |

|

-Y |

0.00175 |

0.01 |

|

+X,-Y |

0.00050 |

0.01 |

|

-X,+Y |

0.00025 |

0.01 |

|

-X,-Y |

0 |

0 |

|

+X,+Y |

0.00050 |

0.01 |

|

-Z |

0.00050 |

0.01 |

Key Highlights

Here are some other key highlights and metrics acquired from testing:

- Across 360 trials, variations between the initial and final reading never exceeded +/- 0.01mm (0.4 thou)

- The mean deviation across all 320 trials was 0.0005mm

Conclusion

The testing results inspire a high level of confidence in the capabilities of the production model. The data showcases that it possesses an exceptional level of repeatability and precision. It assures us that the production model will be capable of providing precise cuts at different speeds and along different axes repeatedly over several cycles, which means smoother and higher quality engravings. We are offering industrial level performance at a hobby price and data such as this truly backs up that claim!

Full results and details on the experimental procedure can be found here

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.